Zenith SPPS: Manufacturing Execution System

The most important challenges modern enterprises face are improvement of production effectiveness, quality of customer service, reduction of expenses and production prime cost.

Both business-applications complexes automating resources management, accounting and analytical work and the systems, being individual components of such complexes, are used at present to solve this problem. Such systems, realizing one or several control enterprise functions, possesses an increased flexibility and integration possibilities with other information products.

Russian Manufacturing Execution System Zenith SPPS is an integrated software product realizing the function of operational manufacture management, allowing to preserve the balance between the number of orders and production capacities necessary for their fulfillment.

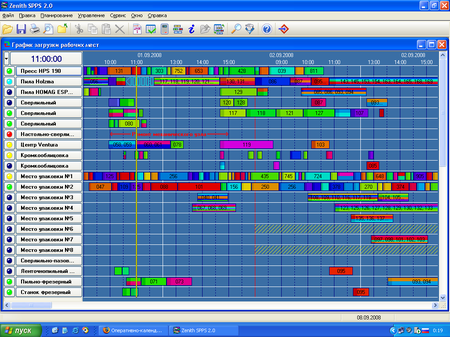

Рабочее место диспетчера

The principle of the system operation consists in planning of capacities and continuous support of the production schedule on the basis of data about the state and workload of equipment (machine tools, instrument aids, etc.) and availability of resources at each moment of time.

Zenith SPPS integrates operational scheduling (calculation, correction and computer support of production schedules) and supervisory control of motion and availability of parts starting with order formation and finishing with output of finished products.

The system can receive data from the modules of manufacture automated technological preparation; direct input of all needed data is fully supported. The results of the system’s work can be saved in the files of different formats (XLS, HTML, XML and others) and serve as initial data for other business applications.

Features of the system

-

Highly productive core

It allows to calculate a schedule with several thousands positions in a few minutes. Use of combinations of different criteria gives a possibility to choose the best algorithm of calculation.

The system possesses powerful means for support of the schedule life cycle: correction, addition of new orders, removal of obsolete data. Change in the schedule of the subdivision operation and addition of new equipment without recomputation of the schedule is allowed.

The system has shown its efficiency at simultaneous use of 5000 technological operations of route technology at 200 work places with planning horizon of up to 12 months.

-

Ergonomic user interface

-

Networking capabilities

There are used in the system:

- an automated work place of the shop dispatcher (the main system module that is simultaneously the applications server);

- work places of production divisions foremen (input of data about fulfillment of the current operations and state of equipment).

- Openness and flexibility

Versatility of the system core and flexible interface allow to adapt Zenith SPPS for various spheres of activity and business processes: from tool production and machining to oil-and-gas production, education needs and logistics. The system can be used both independently and jointly with other software.

-

Availability to a wide range of enterprises

The cost of license and complete introduction of the system by order is lower than for other systems with similar functionality, which makes its accessible even for small companies. The presence of a fast-deploying base version allows to install the system very quickly and with the expenditures minimal.

Substantiation of the system introduction

The use of the Zenith SPPS system allows to considerably improve the following indices of the enterprise:

- growth of labor productivity;

- increases in the equipment load factor;

- decreases in the volume of incomplete production;

- increases in the level of "transparency" and controllability of the production processes;

- improvement of in-time delivery percentage.

Expenditures for introduction of the Zenith SPPS system is a balanced investment in effective management of production subdivisions of an enterprise.

Development stage

Finished product. Zenith SPPS is applied at a number of enterprises in Russia.